Material Issue

Introduction

Introduction

Introduction:

Material Issue window used to issue the material against the Indent raised.

Business case:

In an industry, once the manufacturing order is released by the planning person. The production supervisor will raise a material indent to the store person. Based on the raised Indent Material Issue will be done.

Tabs

Material Issue

Critical Fields:

1) Date Required & Account Date - Date required and Account date need to be selected.

2) Warehouse - Reference from Material indent source warehouse.

Critical & onetime setup fields:

1) Organization Field- This Field is used to select the organization which you are going to process the order.

2) Target Document Type- This Field is used to select the type of the document that you are going to process.

Non-Critical Fields:

1) User/Contact - The Person who is requesting the indent.

2) Project- If this order is processed against a project user can tag the project for tracking.

3) Campaign - If this order comes with the mobile marketing campaign

Serial number/Lot number (ASI):

The values of the actual Product Attribute Instances. The product level attributes are defined on Product level.

Zoom conditions:

1) Material Indent

Customization:

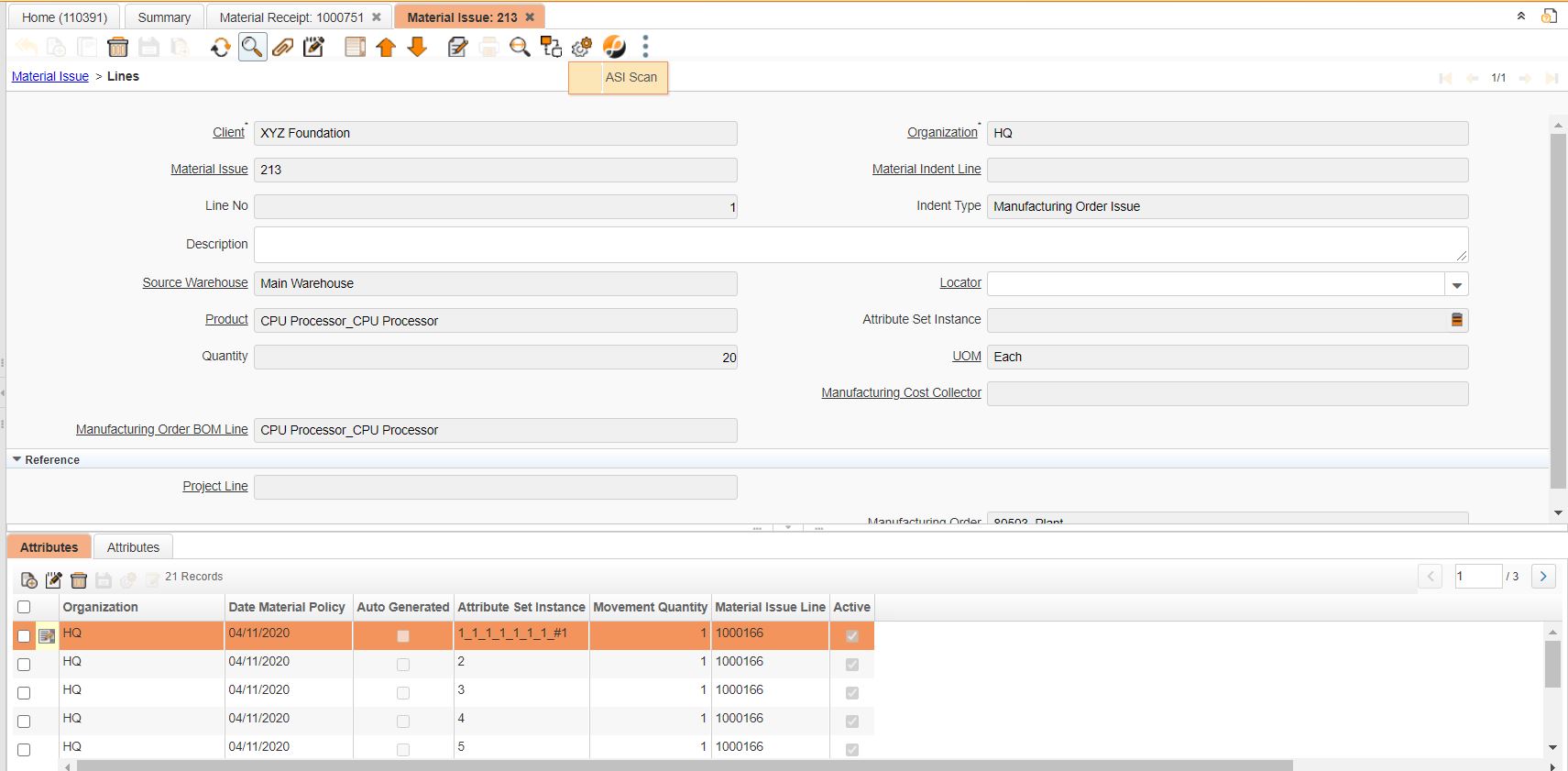

Material Issue Lines

Substitute serial number to be searched in ASI Search process.

2)ASI Search: The ASI Scan option in the process button allows users to scan multiple serial numbers, which will then populate the corresponding serial numbers in the Attribute tab

Document Actions

Validations

Save:

System check whether all the mandatory field are filled

Delete:

System will check the data's provided and change the document status to In progress status.

Document action prepare:

System will check the data's provided and change the document status to In progress status.

Document action complete:

System will change the document status to complete.And make the Indent to visible in Material Issue Screen.

Document action void/reverse correct actual:

Void- system will reverse all the cost transaction data's and change the document status to Void

Document action close:

Actions

Verify:

Not applicable

Create lines from:

1) If Manufacturing document number is selected system will display the material need to be issued based on the concern manufacturing order number.User can select the product that need to be issued and enter the Issue quantity.

2)If Material Indent document number is selected system will display the material need to be issued based on the concern Material Indent number.User can select the product that need to be issued and enter the Issue quantity.

Copy from/lines:

Not applicable

<custom actions>

Process

Issue Process

1) ASI Product Scan : Its help to scan multiple serial numbers and it will populate concurrent serial numbers in Attribute tab

Issue Line process

1) ASI Scan : Its help to scan multiple serial numbers and it will populate concurrent serial numbers in Attribute tab

Videos

Videos

https://www.youtube.com/watch?v=q814_Mj1iPM

Reports

| S.NO | Report type | Report Name | Report Purpose |

| 1 | Menu Report | Material Indent to Issue with stock | This report is used to track Material issued quantity against material request quantity with on-hand stock. |