Quality Inspection (Single)

Introduction

Window Introduction

Introduction

Inspection Single window is used to Inspect a product,This window provide you the inspection result based on the test plan provided.This window is used while receiving the component,while selling the component,While moving the component to internal warehouse etc.

Business Example

In a pump Industry there will be various stages of inspecting the component.Once the purchase material is in-warded Inspection will be completed and stock will move to stores.During a job order material is in warded material will be inspected,While moving the component to another warehouse,While issue the component to production,while taking receipt of the finished goods to stores and during shipment process.These transactions will be carried out in this window.

Tabs

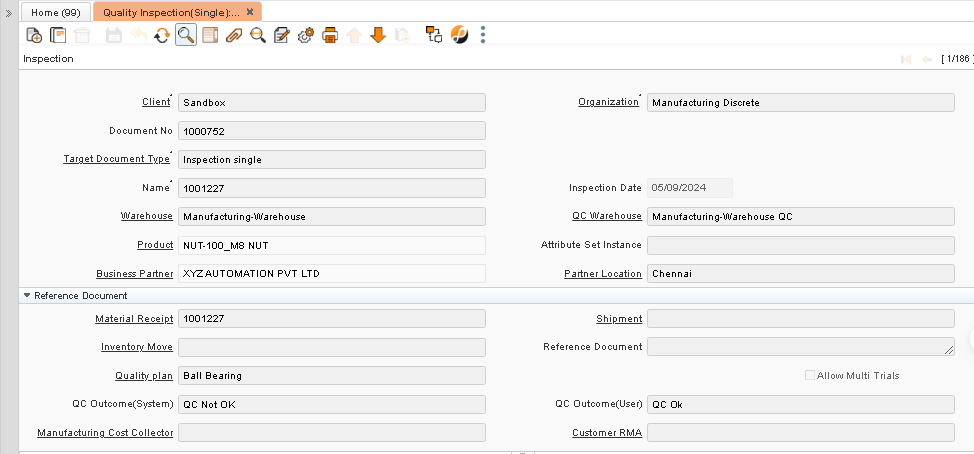

Inspection

1) Name- Enter the Name of the document.

2) Tester- Name of the person who is inspecting the component.

Critical & onetime setup fields

1) Organization Field- This Field is used to select the organization which you are going to process the order.

2)Target Document Type- This Field is used to select the type of the document that you are going to process.

Non-Critical Fields

1) Total Quantity- System will display the quantity from the selected Material receipt document.User can edit the Quantity.

2) Sample Quantity- System will display the quantity from the selected Material receipt document.User can edit the Quantity.

Serial number/Lot number (ASI)

Attribute cant be created in this document.Only attribute will be taken from the selected Source document.

Zoom condition’s

1) Material Receipt

2) Shipment (Customer)

3) Subcontract Receipt

4) Inventory Move

5) Internal Use Inventory

6) NCR

Customization

Results

Critical Fields

1) Parameter- Multiple parameters may be there for inspecting a product.This will be shown from Test Plan which the user selected for the product.

2) Record Value- The value that acquired in real during Inspecting the parameter need to be entered.

3) Total Qty- Number of quantity which are inspected.

4) Qc outcome (User)- If decision from the system need to changed this option can be used.For using this option need to configure in the test plan against the parameter.

Critical & onetime setup fields

Non-Critical Fields

1. Sample Quantity: Sample quantity to be inspected.

2. Reason: Reason for QC Outcome (User), being entered by user manually.

Serial number/Lot number (ASI)

Zoom condition’s

Validation

Attributes

Critical Fields

Critical & onetime setup fields

Non-Critical Fields

Serial number/Lot number (ASI)

If there multiple attribute for single product this will display in attributes Sub tab.

Zoom condition’s

Validation

Consumables

Critical Fields

1) Product- Enter or select the product that needs to be consumed.

2) UOM: Unit of Measurement of Product to be inspected.

3) Quantity- This field represents the quantity needs to be consumed additionally while inspecting.

4) Charge- For posting cost of the consumed product.

Critical & onetime setup fields

Non-Critical Fields

Serial number/Lot number (ASI)

Zoom condition’s

Validation

Quality Tools

It's use to add asset and change test plan.

Document Actions

Validations

Save

1) System will check whether all the Mandatory Fields are filled.

2) System will generate the document number.

3) System will check whether a valid quality test plan is provided.

Delete

System will delete the order and its history from the database.This can be done only when the document status is Draft status and In progress Status.

Document action prepare

1) System will check the Product,Test plan,Previoust document and convert the document status to In progress.

2) System will check the Period control for the document date whether it is open.

Document action complete

System will complete the document and move the accepted stock to stock.

Document action void/reverse correct actual

1) Void- system will reverse all the cost transaction data's and change the document status to Void

Document action close

Actions

Verify

Create lines from

Transactions- There are multiple transaction that can be Inspected using this window listed below,

a) Material Receipt/Customer Return- The material from vendor and return rejection material from customer.

b) Shipment- Before sending to customer,Finished goods can be inspected.

c) Inventory Move- Moving the Product Internally form one warehouse to other.Material can be Inspected.

d) Manufacturing Order Issue- While issuing the product to Production Material can be inspected.

e) Manufacturing Order Receipt- While receiving the Finished goods to stock after production completion.

f) Internal Use Inventory- While you consume the product internally material can be inspected.

g) Subcontract Receipt- While receiving the Material from the subcontractor material can be inspected.

Copy from/lines

<custom actions>

Process

There are 2 process in Inspection Single Window.

Create Lines from

Create lines from process is used to create the Inspection data details like product and document numbers from the Material Receipt or Job Work Receipt or Customer Return Document Types.

Generate NCR

Generate NCR process is used to generate NON Confirmation Report for the Inspected Document.

This Process creates New NCR Document in that window.

Video

Reports

| Sr.No | Report Name | Report Purpose |

| 1 | Inprocess Inspection Report | This Report is used to get details about the inspection Production . |

| 2 | Inspection Pending Report (InProcess) | This Report Gives the Details about the Inspection Production With Pending Quantity and Activity Control Report No. |

| 3 | Inspection Pending Report Purchase | This Report gives the Purchase Inspection details with Pending Quantity. |

Quality Tools

It's use to add asset and change test plan.