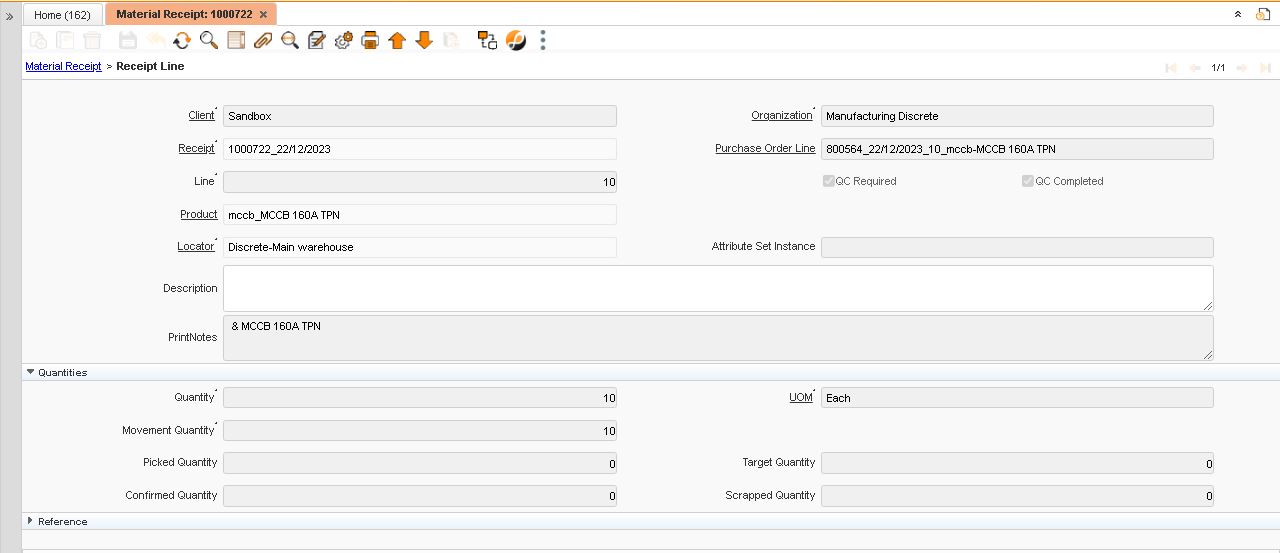

Material receipt line

Critical Fields:

1.Product : To select the product type is item, you can select the multiple product in this line item

2.Quantity : Enter the received quantity against the Material receipt.

3.Locator- The Locator indicates where in a Warehouse a product is located.

4.UOM: The record will populate from product and we can change the UOM manually, if uom conversion for the product.

5.QC required: If Qc is enabled for the product mentioned in material receipt lines then this check box will be ticked automatically if we complete the material receipt document.

6.QC completed : This check box will be ticked if QC inspection (Single/Bulk) is completed against the concern material receipt.If inspection found not ok then NCR document should be completed.

Critical & onetime setup fields:

Non-Critical Fields:

1.Description: Used to describe specifics about a purchase document or any other note, information, or data, for example.

2.Print Note: Used to describe specifics about a purchase document or any other note, information, or data, for example.

3.Project: If this order is processed against a project user can tag the project for tracking.

4.Project task: Actual project task in a project.

5.Project Phase: Phase of project.

6.Campaign: Type of planning made during Phase of project.

7.Activity: Activity carried out during Phase of project.

Serial number/Lot number (ASI):

In this Field we can set Attribute instance for this product & we will generate serial number in material receipt line for each quantity or total quantity

Zoom conditions:

Customization:

No Comments