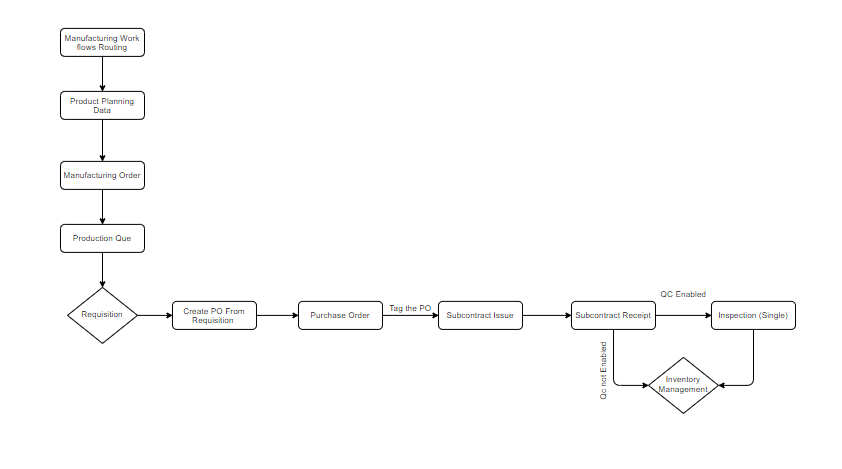

Module Flow

Input:

1) Manufacturing Work Flows Routing

2) Product Planning Data

3) Manufacturing Order

Process:

1) Production Que

2) Requisition

3) Create PO From Requisition

4) Purchase Order

5) Subcontract Issue

6) Subcontract Receipt

7) Quality Inspection

Report:

1) Subcontract Issue Overview Report

2) Subcontract open Receipt Report

3) Subcontract Receipt Overview Report

Data transfer:

1) Inventory Management

a) KA_SUBCONTRACT_MOVEMENT_CREATE - This will direct the system to create a Subcontract movement instead of regular Inventory Movement to the Subcontract warehouse

b) KA_SUBCON_PRODUCT - Specifies the default product to be used for Subcontract PR/PO, the value(search key) should be mentioned here, the other place is resource master.

c) KA_SUBCON_PURCHASE_MANDATORY- In subcontract Issues, if a purchase order is nonmandatory configuration can be used. The default value is True.

1) Node Product Not mandatory if fixed either in resource master or globally(delivered in the previous ticket)

2) New Create from line option in the Issue document that will pull all the items from MO Bom also can be pulled from exclusive BOM.

3) Subcontract Receipt Create lines enhanced to show all 3 types of items now.

a) Issue Items(all types)

b) PO line items & Charges

c) WIP Items(new) - MO Header material and Phantom Items in BOM

No Comments