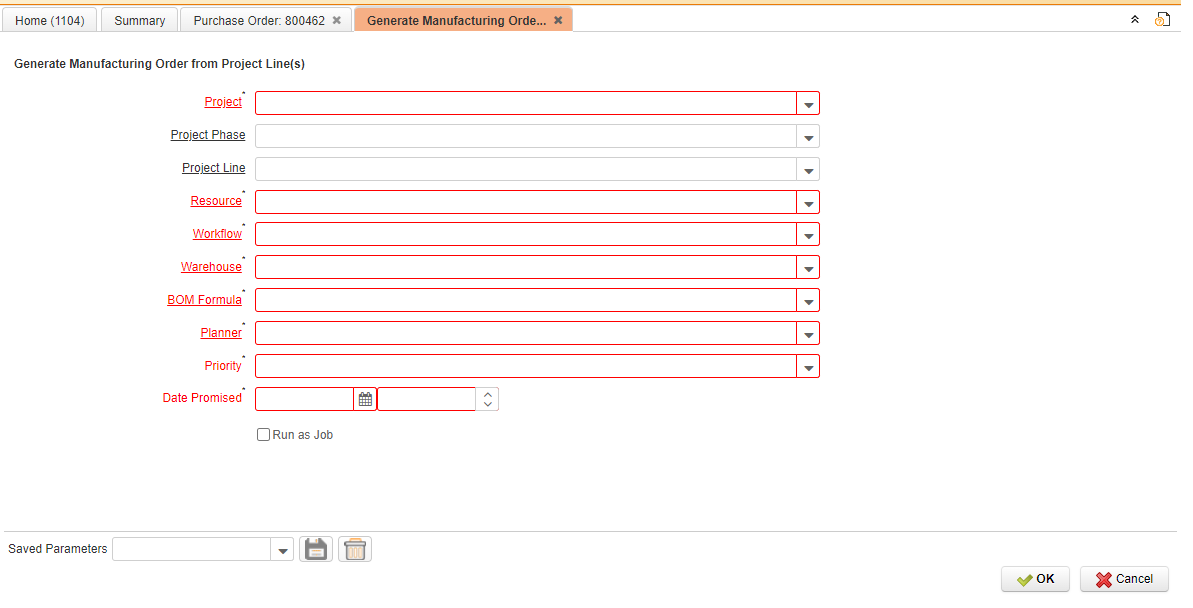

Generate Manufacturing Order from Project

Parameter :-

1.Project : a series of tasks that must be accomplished in order to achieve a specific result, including phases and phase lines as sequential tasks to complete a project. It is master data.

2.Project Phase : Phase lines are series of duties to complete a project which contains activities, task and task lines.

3.Project Line : Project lines are successive steps to be followed.

4.Resource : It is used to Select the manufacturing work center (previously defined) where you want to execute the operation. For the product costing, the Resource rate is taken from the cost element introduced in the window Product Costing (Refer resource master).

5.Workflow : Workflow to be choosed from the product planning data window as per your master configuration.

6.Warehouse : Select a warehouse where the final product needs to be stored.

7.BOM Formula : It is used to select bill of material formula created for the product.

8.Planner : Name of the person who is planning the Manufacturing order

9.Priority : The Priority indicates the importance of this request.

10.Date Promised : This field represents the date that this order needs to be completed.

Process :-

This Process is used to Generate Manufacturing order from Project

No Comments