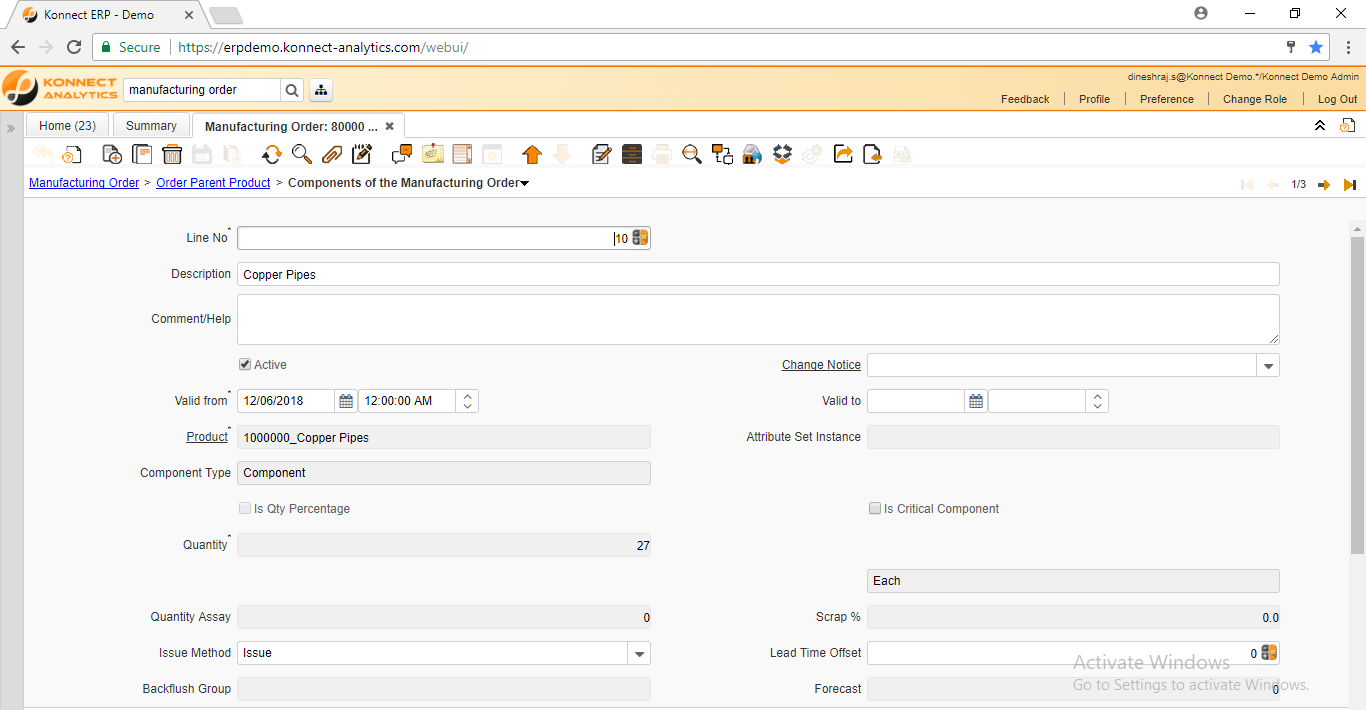

Order Parent Product

NOTE: Manufacturing Order->Order Parent Product->Components of the Manufacturing order

Critical Fields

1) Product- Enter the child component

2) Quantity- System will multiply the quantity provided in Workflow Routing and display automatically.If manual entry,Enter the Child quantity required for production

3) Issue Method- There are two methods for issue the components to the Manufacturing order

a) Method Issue: The component are delivered one for one and is necessary indicate the delivered quantity for each component.

b) Method BackFlush: The component are delivered based in BOM, The delivered quantity for each component is based in BOM or Formula and Manufacturing Order Quantity.

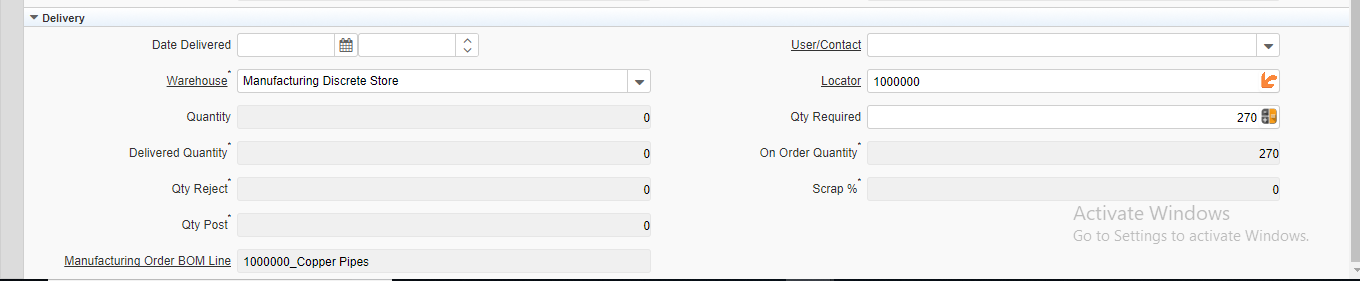

4) Warehouse- The Warehouse identifies a unique Warehouse where products are stored or Services are provided.

5) Locator- The Locator indicates where in a Warehouse a product is located.

6) Unit of Measurement

Critical & onetime setup fields

Non-Critical Fields

1) User/Contact- The User identifies a unique user in the system. This could be an internal user or a business partner contact

2) Scrap%- Scrap is useful to determinate a right Standard Cost and management a good supply.

3) Change Notice- This field represents the Bill of material's change Notice Revision.

Serial number/Lot number (ASI)

The values of the actual Product Attribute Instances. The product level attributes are defined on Product level.

Zoom condition’s

1) MRP

2) Production Issue and Receipt

Validation

No Comments